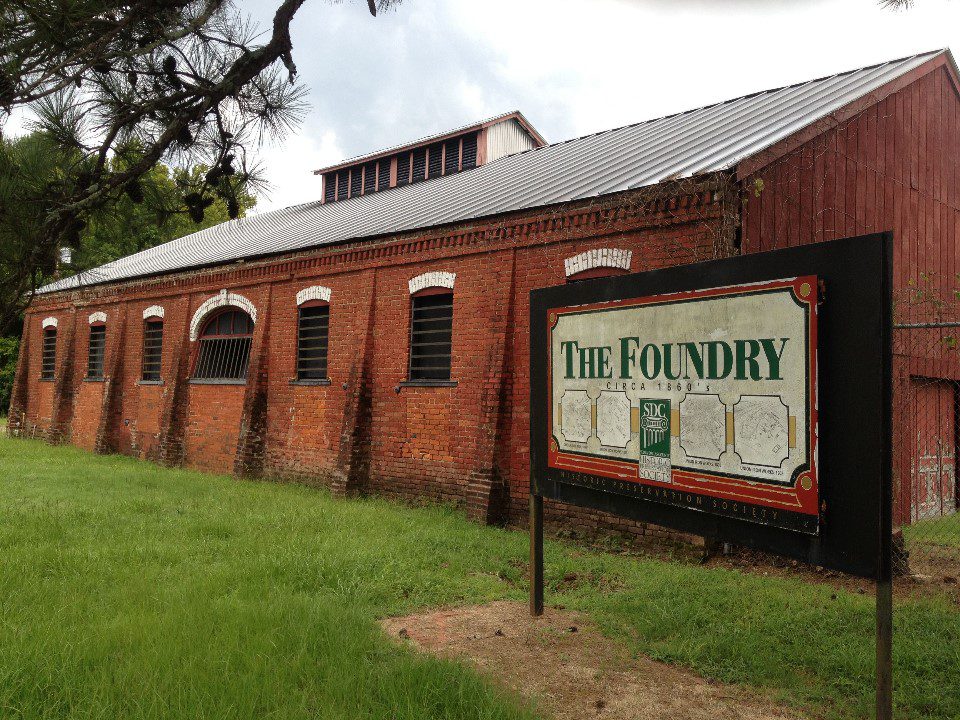

The Selma Naval Foundry stands as a cornerstone in the annals of weapon manufacturing, particularly during the American Civil War. As a pivotal hub for the Confederate armed forces, its strategic significance was only surpassed by the Tredegar Ironworks in Richmond, Virginia.

Boasting a workforce of up to 10,000 employees and a diverse array of production facilities, it held a critical role in supplying arms and munitions. Its geographical placement along the Alabama River facilitated access to essential raw materials, while robust rail connections ensured the swift transportation of goods to Mobile Bay.

The foundry's destruction by Union forces in 1865 had far-reaching implications, impacting the South's military capabilities.

Today, the Selma Ordnance and Naval Foundry upholds this legacy, producing a wide spectrum of small arms ammunition for military and law enforcement applications, with a high annual production capacity and stringent quality control standards.

Key Takeaways

- Selma Naval Foundry was a leading manufacturing center for the South during the Civil War, producing finished war materials for the Confederate armed forces.

- It was the second largest producer of war materials after the Tredegar Ironworks in Richmond, Virginia.

- The foundry manufactured a variety of items including cannon, shovels, uniforms, swords, and buttons.

- Selma's manufacturing facilities and equipment were destroyed by Union forces in 1865, contributing to the South's eventual defeat.

The historical significance of Selma Naval Foundry lies in its pivotal role as a leading manufacturing center for the South during the Civil War, producing crucial war materials for the Confederate armed forces. This had a profound impact on the local economy, as the foundry employed as many as 10,000 workers and was second only to the Tredegar Ironworks in Richmond, Virginia, in the production of war materials.

Its contributions to the Confederate armed forces were immense, as it manufactured a wide range of items, including cannon, uniforms, and swords. The foundry's strategic location and access to resources allowed it to play a significant role in the South's ability to continue fighting in the latter part of the war.

The destruction of Selma by Union forces in 1865 marked the end of its manufacturing capabilities, but its legacy in supporting the Confederate armed forces remains undeniable.

Evolution of Selma Ordnance Facility

Selma Naval Foundry has evolved into the Selma Ordnance and Naval Foundry, playing a pivotal role in the production of small arms ammunition for military and law enforcement use. Established in 1941 as the Selma Arsenal, it has since expanded its operations during the Korean and Vietnam Wars. Renamed in 1972, the facility now occupies 2,000 acres and consists of multiple manufacturing buildings, testing and quality control facilities, and a dedicated storage area for finished products. With an annual production capacity of 1.5 million rounds of ammunition, it utilizes advanced machinery and technology, operates 24/7 with a skilled workforce of over 500 personnel, and continuously innovates and develops new ammunition types. The table below illustrates the production capacity, product range, and quality assurance of the Selma Ordnance and Naval Foundry.

| Production Capacity | Product Range | Quality Assurance |

|---|---|---|

| 1.5 million rounds annually | Small arms ammunition for military and law enforcement use | Adherence to strict quality control standards, rigorous testing procedures, and compliance with industry regulations and specifications |

This evolution signifies significant advancements in ammunition production, positioning Selma as a crucial contributor to national defense capabilities.

Infrastructure and Facilities at Selma

Occupying over 2,000 acres, the Selma Ordnance and Naval Foundry encompasses multiple manufacturing buildings, testing and quality control facilities, and a dedicated storage area for finished products.

The sheer scale of the manufacturing buildings evokes a sense of awe, showcasing the immense capabilities of the facility.

The meticulous attention to testing and quality control instills confidence in the precision and reliability of the products.

The dedicated storage area for finished products symbolizes the culmination of hard work and dedication, ensuring a ready supply of essential munitions for defense.

The comprehensive infrastructure and facilities at Selma Ordnance and Naval Foundry stand as a testament to the unwavering commitment to excellence in selma ordnance storage, testing, and quality control.

Production Capacity and Capabilities

With an annual production capacity of 1.5 million rounds of ammunition, our facility at Selma Ordnance and Naval Foundry is equipped to produce various calibers and types of ammunition using advanced machinery and technology. The Selma Ordnance expansion has enabled us to meet the increasing demand efficiently. Incorporating state-of-the-art production technology advancements has further enhanced our capabilities.

Our skilled workforce of over 500 personnel ensures seamless 24/7 operations to meet demand and deadlines. We specialize in manufacturing small arms ammunition, including a wide range of calibers such as 9mm, .223, and .308, catering to both civilian and military needs. Furthermore, our facility is capable of producing specialized ammunition for law enforcement and military applications.

Adhering to stringent quality control standards, every batch of ammunition undergoes rigorous testing and thorough inspections to ensure compliance with industry regulations and specifications.

Range of Ammunition Manufactured

The Selma Ordnance and Naval Foundry manufactures a diverse range of ammunition for various applications.

The variety of ammunition types ensures readiness for any combat scenario, instilling confidence in the military's capabilities.

This wide range caters to the specific needs of law enforcement, military, and civilian users, ensuring their operational effectiveness.

The precision and expertise involved in the ammunition production process exemplify the commitment to delivering high-quality, reliable products, fostering trust and dependability.

The continuous innovation in developing new ammunition types showcases a dedication to staying ahead of evolving threats, evoking a sense of security and preparedness.

This demonstrates the Selma Naval Foundry's commitment to producing a comprehensive array of ammunition, utilizing cutting-edge technology and stringent quality control measures.

Quality Control Measures

Quality control measures at Selma Naval Foundry ensure the consistent production of high-quality and reliable ammunition. The importance of quality control cannot be overstated, especially with the advancements in ammunition technology. Selma Naval Foundry adheres to strict quality control standards and implements rigorous testing procedures for every batch of ammunition. This includes thorough inspections of raw materials and components to ensure compliance with industry regulations and specifications. The foundry also maintains a record of product performance and customer feedback to continuously innovate and develop new ammunition types. The table below highlights the key quality control measures at Selma Naval Foundry:

| Quality Control Measures | Description |

|---|---|

| Adherence to Standards | Strict compliance with industry regulations and specifications |

| Rigorous Testing Procedures | Thorough inspections and testing for every batch of ammunition |

| Continuous Innovation | Development of new ammunition types based on customer feedback |

| Record Maintenance | Keeping a record of product performance and customer feedback |

These measures reflect the commitment to delivering high-quality and reliable ammunition.

Selma Naval Foundry's production of high-quality and reliable ammunition has had a significant impact on military operations and national defense capabilities.

- The foundry's contribution to the Confederate war efforts during the Civil War ensured the South's ability to continue fighting in the last two years of the war. This impact was crucial in sustaining the war efforts and prolonging the conflict.

- Additionally, the economic growth spurred by the foundry's operations has been instrumental in bolstering the region's industrial development and overall prosperity. The foundry's presence has led to the creation of jobs and the establishment of ancillary industries, driving economic progress in the area.

- The legacy of Selma Naval Foundry continues to resonate, underscoring the pivotal role it played in shaping the nation's military history and economic landscape.

Role in Military and Law Enforcement

Playing a pivotal role in supplying high-quality ammunition, the Selma Naval Foundry has significantly contributed to the military and law enforcement sectors. The foundry's annual production capacity of 1.5 million rounds of ammunition, advanced machinery, and skilled workforce of over 500 personnel have enabled it to meet the demanding needs of the military and law enforcement agencies. Its product range includes specialized ammunition for rifles, pistols, and shotguns, catering to the specific requirements of law enforcement and military use. The foundry adheres to strict quality control standards, conducting rigorous testing procedures for every batch of ammunition to ensure compliance with industry regulations and specifications. By consistently innovating and developing new ammunition types, the Selma Naval Foundry continues to play a crucial role in enhancing the capabilities of the military and law enforcement.

| Production Capacity | Product Range | Quality Assurance |

|---|---|---|

| 1.5 million rounds annually | Specialized ammunition for law enforcement and military use | Adherence to strict quality control standards |

Future Innovations and Developments

The upcoming expansion at the Selma Naval Foundry will involve implementing cutting-edge technology to enhance production efficiency and meet the evolving demands of the military and law enforcement sectors. This commitment to future advancements and technological progress is essential for maintaining a competitive edge in the industry.

The following are key aspects of the upcoming innovations and developments at the foundry:

- Integration of advanced robotics and automation systems to streamline manufacturing processes. This will reduce production time and increase output capacity.

- Implementation of state-of-the-art quality control measures to ensure the highest standards of ammunition. This will guarantee superior performance and reliability in the field.

- Research and development initiatives to create innovative ammunition types that address emerging security challenges. This will demonstrate a commitment to staying ahead of evolving threats and operational requirements.

Frequently Asked Questions

During the Civil War, Selma Naval Foundry manufactured various types of artillery, including cannon such as the 7-inch Brooke rifle, and also produced small arms ammunition for rifles, pistols, and shotguns. The foundry played a crucial role in Confederate military operations.

How Did the Destruction of Selma's Manufacturing Facilities Impact the Confederate Forces' Ability to Continue Fighting in the Last Two Years of the Civil War?

The destruction of Selma's manufacturing facilities severely impacted Confederate forces' ability to continue fighting in the last two years of the Civil War. It disrupted the supply chain, hampering the production and distribution of crucial war materials, hindering their combat effectiveness.

How Did the Location of Selma, Alabama Contribute to Its Significance as a Manufacturing Center During the Civil War?

The location of Selma, Alabama, was pivotal in its industrial significance during the Civil War. Its central position in the Confederacy, access to Mobile Bay, and proximity to iron and coal fields contributed to its manufacturing prowess. Geographical advantages enhanced its role as a crucial weapon manufacturing center.

The renaming of Selma Arsenal to Selma Ordnance and Naval Foundry in 1972 was driven by the facility's expanded focus on manufacturing naval weaponry and ammunition. Factors included enhancing production capabilities and aligning with evolving military needs.

Selma Ordnance and Naval Foundry has introduced innovative developments in ammunition types, catering to law enforcement and military needs. The facility's cutting-edge technology and skilled workforce ensure the production of a wide range of high-quality ammunition.

Conclusion

The Selma Naval Foundry stands as an unparalleled symbol of industrial prowess and strategic significance. It shaped the course of military history with its unparalleled production capacity and unwavering commitment to quality. Its impact on the Confederate armed forces during the Civil War and its continued role in supplying small arms ammunition for military and law enforcement use solidify its position as an indispensable asset for national defense.

The Selma Naval Foundry's legacy of innovation and resilience ensures its enduring influence on the future of weapon manufacturing.

Our Reader’s Queries

On April 2, 1865, Wilson’s troops seized Selma and obliterated the city’s production sites and machinery, such as the arsenal, the ordnance center, the gunpowder works, the nitre works, and 11 ironworks and foundries.

What was the significance of the Battle of Selma?

The trio of marches in Selma marked a crucial moment in the fight for civil rights. Thanks to their powerful impact, the Voting Rights Act of 1965 was introduced to Congress on March 17 of that year. President Johnson then officially turned it into law on August 6, 1965.

What is the history of Selma Alabama?

Selma thrived as a trading hub and market town in the pre-Civil War era, known as the King Cotton days. It played a significant role in producing weapons and building iron ships for the Confederacy during the war, and was fortified with extensive earthworks for defense.

Who was the Union general at the Battle of Selma?

March 22, 1865 saw Brevet Major-General James H. Wilson in charge of three divisions of Union cavalry, consisting of around 13,500 men, heading south from Gravelly Springs, Alabama.

Check Out For More References