GE Aerospace Invests in Huntsville: GE Aerospace has recently made a significant investment in its Huntsville manufacturing site, marking a pivotal moment in the company’s expansion strategy. With a substantial injection of $650 million into the facility, GE Aerospace’s commitment to enhancing its manufacturing capabilities is evident.

This move not only underscores the company’s dedication to innovation and growth but also signals a broader trend within the aerospace industry. The implications of this investment extend far beyond Huntsville, hinting at a larger transformation that is poised to reshape the aerospace landscape.

GE Aerospace Invests $650 Million in Manufacturing Sites and Supplier Partners

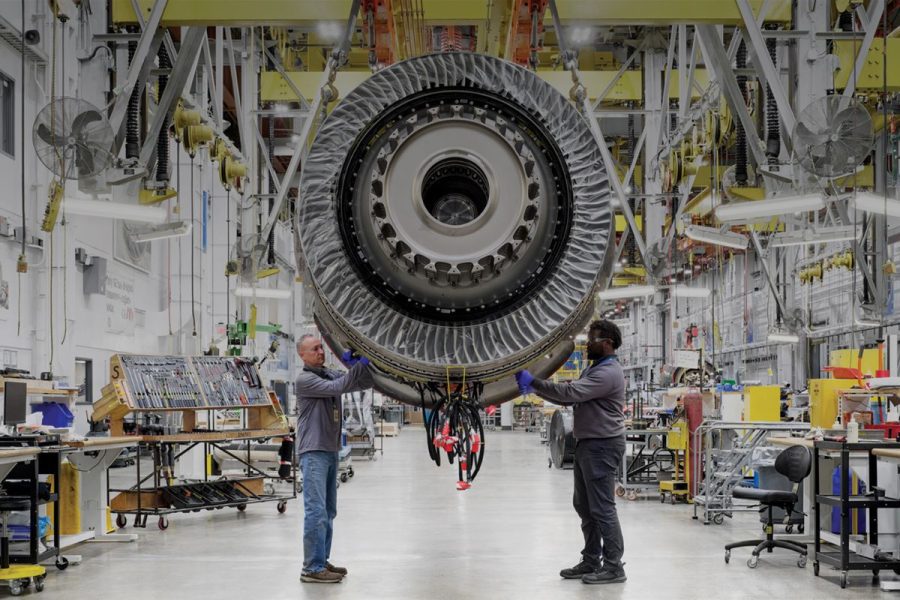

GE Aerospace’s strategic initiative to invest $650 million across its manufacturing sites and supplier partners underscores a significant commitment to enhancing production capabilities and infrastructure within the aerospace industry.

This substantial investment aims to bolster manufacturing processes, improve efficiency, and drive innovation in the production of narrowbody and widebody aircraft engines. A portion of this investment, totaling $16.8 million, is specifically allocated to the Huntsville site, highlighting the company’s dedication to advancing manufacturing capabilities at this location.

The funds will be utilized to procure state-of-the-art machinery, quality testing equipment, and facility upgrades, all tailored to support the production of cutting-edge materials like Ceramic Matrix Composites. These materials play a vital role in enhancing thermal management and reducing overall weight in aircraft engines.

GE Aerospace’s commitment to innovation and sustainability is evident through this investment, positioning the Huntsville facility as a key player in shaping the future of aviation technology.

ALSO READ: Inmate Sues Baldwin Sheriff for Abuse: Shocking Allegations

GE Aerospace Expansion Extends Across Multiple Locations

With an expansive investment strategy covering various locations, GE Aerospace is strategically enhancing its operational capabilities and solidifying its presence in key aerospace sectors across the United States. The company’s ambitious investment plan extends beyond Huntsville, with funds allocated to enhancing operations at key sites nationwide.

A significant portion of the investment is earmarked for Auburn, Alabama, underlining GE Aerospace’s commitment to bolstering manufacturing capabilities in the region. Furthermore, resources are being directed towards four facilities in North Carolina, reinforcing the company’s foothold in the state’s aerospace sector.

In addition, GE Aerospace is set to invest in facilities in the Cincinnati area, highlighting its comprehensive approach to strengthening its manufacturing footprint. This widespread investment initiative underscores the company’s dedication to driving innovation, improving production efficiency, and maintaining its position as a leader in the aerospace industry.

News in Brief

“GE Aerospace Invests $650 Million to Advance Manufacturing and Innovation: GE Aerospace recently announced a $650 million investment across its manufacturing sites and supplier partnerships, with $16.8 million allocated to its Huntsville facility. The investment aims to enhance production capabilities for narrowbody and widebody Aircraft Engines, focusing on state-of-the-art machinery and testing equipment.

Huntsville’s role in producing materials for Ceramic Matrix Composites underscores GE Aerospace’s commitment to innovation. Stephen French, site leader, emphasized the site’s significance in shaping aviation’s future. The expansion extends to Auburn, Alabama, and four facilities in North Carolina, showcasing GE Aerospace’s dedication to strengthening manufacturing across the U.S. The investments highlight the company’s commitment to driving innovation and reinforcing its position as an industry leader.”